BDM series

Explosion-proof cable clamping sealed connector

1. It is widely used in flammable and explosive gas environment such as oil exploitation, refining, chemical industry, offshore oil platform, oil tanker, etc. It is also used in flammable dust places such as military industry, port, grain storage and metal processing;

2. Applicable to Zone 1 and Zone 2 of explosive gas environment;

3. Applicable to IIA, IIB, IIC explosive gas environment;

4. Applicable to areas 21 and 22 of flammable dust environment;

5. Cables for use in explosion-proof electrical appliances in hazardous areas of petroleum and chemical companies Introduced for use.

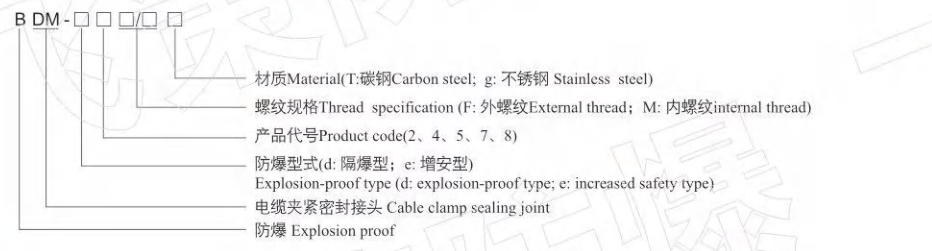

Model Implication

Features

1. Explosion-proof type is explosion-proof type, increased safety type, dust explosion-proof type.

2. According to the material, it is divided into aluminum alloy, high quality carbon steel, stainless steel, engineering plastics, high quality brass and so on.

3. It adopts mechanical cable clamping structure and is equipped with anti-lifting device.

4. The product is available in a form suitable for holding armored cables and non-armored cables.

5. The surface of the product is provided with a laser-engraved permanent “Ex” explosion-proof mark.

6. The thread form has various forms such as metric thread, NPT thread and pipe thread, which can be selected according to user's site requirements.

Main Technical Parameters

Order Note

1. Select one by one according to the rules in the model meaning, and add the explosion-proof mark after the model meaning. The specific embodiment is: "Product specification model code + explosion-proof mark". If the explosion-proof cable clamp sealing joint is required, the product code is type 2, the A-end thread is , and the anti-corrosion grade is F2. The product model is: “BDM-d 2 type + Ex dIIC Gb Ex tD A21 IP66.”

2. If the user has special needs, it must be specified at the time of ordering